This product features an optical path design with a MOPA structure, capable of generating ns-level pulse width and peak power of up to 15 kW, with a repetition frequency ranging from 50 kHz to 360 kHz. It exhibits high electrical-to-optical conversion efficiency, low ASE (Amplified Spontaneous Emission), and nonlinear noise effects, as well as a wide operating temperature range.

Key Features | Applications |

Eye-safe Wavelength Ns-Level Pulse Width Up to 15kW Peak Power Compact Package Design Low Power Consumption MOPA Structure Support Customization | Laser LiDAR Remote Sensing Distance Sensor Laser Detection |

| Parameters | Unit | Min. | Typical | Max. | Remarks |

| Working Mode | Pulse | ||||

| Wavelength | nm | 1545 | 1550 | 1555 | |

| Pulse Width | ns | 4 | |||

| Repetition Frequency | kHz | 30 | 50 | 100 | Customization |

| Average Power | W | 3 | 6 | Customization | |

| Peak Power | kW | 12 | Customization | ||

| Polarization State | Random | ||||

| Trigger Mode | Internal/External | ||||

| Pulse Output Delay Jitter | ns | 3 | |||

| Electrical Power Consumption | W | 100 | |||

| Working Voltage | V | 28 | |||

| Working Temp.@Shell | °C | -40 | 60 | ||

| Storage Temp. | °C | -40 | 105 | ||

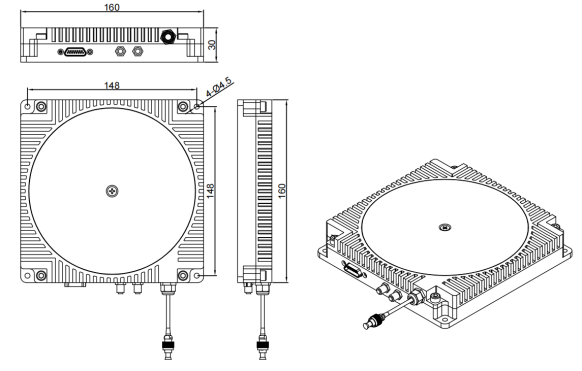

| Package Size | mm | 160*160*30 | |||

| Weight | g | 2000 | |||

| Optical Output Mode | Multimode fiber patch cable | Customization collimating lens | |||

| Length of Output Optical Fiber | m | 0.3 | 3mm sleeve | ||

| Interface mode | J29A-15ZKW | ||||

· Laser Safety: This product emits laser radiation that is not visible to the human eye. Protective goggles should be worn before use. Avoid direct exposure of eyes or skin to the laser beam while the laser is operating.

· Power Usage: Ensure use within the rated voltage and power specifications.

· Electrostatic Protection: Appropriate electrostatic protection measures must be taken during the transport, storage, and use of the light source.

· Fiber End Face: The output end face should be appropriately cleaned before use to ensure it is free from dirt and contamination, as this can easily cause damage to the end face.

· Cooling Requirements: Adequate cooling must be maintained during the operation of the laser. It is recommended to use thermal grease or a thermal pad with high thermal conductivity for efficient heat dissipation. Failure to dissipate heat effectively may cause the internal temperature of the laser to rise, triggering the over-temperature protection feature and shutting down the laser output.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China