Diamonds, revered for their unparalleled beauty, undergo meticulous classification based on natural attributes before they're transformed into the exquisite final products we cherish. While ancient processing techniques endured for centuries, a new era ushered in by laser technology has redefined the diamond industry worldwide.

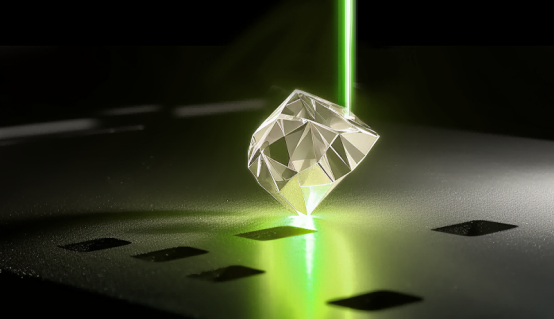

Yes, lasers can indeed cut diamonds, and this technology has revolutionized the diamond-cutting industry. Laser Diamond Cutting offers precision, speed, and reduced waste compared to traditional methods. But how exactly does it work?

As early as the 17th century, initial attempts to revolutionize diamond processing emerged. However, it wasn't until the 21st century that significant advancements were achieved. Einstein's groundbreaking work in 1917 laid the theoretical foundation for laser technology. In 1960, Theodore H. Maiman showcased the world's inaugural functional laser, paving the way for widespread adoption across diverse industries.

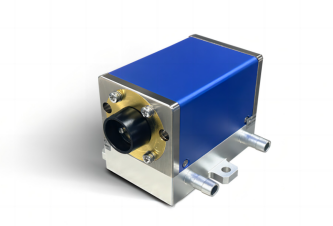

Empowered by cutting-edge technologies like the Diode-Pumped Solid-State Laser (DPSS) and Neodymium YAG laser, laser diamond cutting stands as a game-changer in the diamond cutting landscape. This eco-friendly approach not only enhances precision and efficiency but also empowers consumers to evaluate diamond cuts against established criteria, enabling them to select their perfect piece of jewelry.Lumimetric has provided light sources and technical support to many users in the field of laser cut diamonds, and today has compiled a list of the more common questions about laser gemstone cutting.

Lumimetric has provided light sources and technical support to many users in the field of laser cut diamonds, and today has compiled a list of the more common questions about laser gemstone cutting.

Before the advent of laser cutting, diamonds were primarily cut using mechanical methods such as cleaving, sawing with a diamond-encrusted blade, and polishing with diamond dust. These methods relied on the natural hardness and cleavage planes of the diamond to shape and facet the gemstone (Shi Guangfeng et al., 2018).

The main challenges in Traditional Diamond Cutting and sawing included significant material loss, the risk of fracturing the diamond, limitations in achieving intricate and precise cuts, and the requirement for high craftsmanship skill. Traditional methods were also time-consuming and labor-intensive (C. Hermanns & J. Middleton, 2005).

Laser cutting offers numerous advantages over traditional methods, including precision, minimal material loss, flexibility in creating complex shapes, and increased efficiency. Lasers can cut diamonds without direct contact, reducing the risk of physical damage and allowing for more intricate designs (N. Shankar, 2015).

Laser technology has significantly refined classic diamond cuts by enabling greater precision and creativity. For example, laser cutting allows for the creation of precise facets and angles in classic cuts such as the Round Brilliant, Princess, and Marquise, enhancing the gemstone's brilliance and fire. The technology also facilitates the development of new variations on traditional cuts, offering enhanced light performance and aesthetic appeal (H. Ohfuji et al., 2010).

DPSS (Diode-Pumped Solid-State) lasers and Green Lasers offer distinct advantages in diamond cutting. DPSS lasers are known for their efficiency and ability to produce high-quality cuts with minimal thermal damage. In contrast, Green Lasers operate at a specific wavelength that allows for extremely precise and detailed cuts, making them particularly suitable for intricate designs. Each type of laser caters to different requirements in the diamond cutting process, with DPSS lasers being preferred for their versatility and Green Lasers for their precision (M. Popov et al., 2021).

Shi, G., Han, D., Shukun, W., & Zhu, K. (2018). Analysis and Evaluation of Natural Diamond Cut by Water Jet - guided Laser. Proceedings of the International Conference on Mechanical Engineering and Automation, 45.

Hermanns, C., & Middleton, J. (2005). Laser separation of flat glass in electronic-, optic-, display-, and bio-industry (Invited Paper). SPIE Proceedings.

Shankar, N. (2015). Cool Laser for Cutting Diamonds. Laser Technik Journal, 12(1), 27–29.

Ohfuji, H., Okuchi, T., Odake, S., Kagi, H., Sumiya, H., & Irifune, T. (2010). Micro-/nanostructural investigation of laser-cut surfaces of single- and polycrystalline diamonds. Diamond and Related Materials, 19(10), 1040–1051.

Popov, M., Bondarenko, M., Kulnitskiy, B., Zholudev, S. I., Blank, V., & Terentyev, S. (2021). Impulse laser cutting of diamond accompanied by phase transitions to fullerene-type onions. Diamond and Related Materials.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China