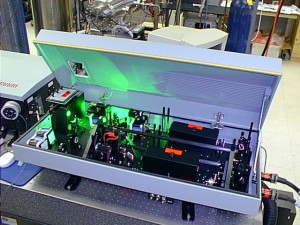

Nd:YAG laser with lid open showing frequency-doubled 532 nm green light

* This image was created by Kkmurray and is licensed under the GNU Free Documentation License, This file is licensed under the Creative Commons Attribution 3.0 Unported license.

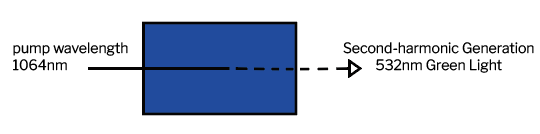

Diode pumped solid state laser utilizes a typical configuration for Frequency doubling: an infrared input beam at 1064 nm is converted into a green 532-nm wave as it passes through a nonlinear crystal. This process, known as Frequency doubling or second harmonic generation (SHG), is a widely adopted method for generating light at shorter wavelengths.

The process begins with a laser diode, which emits infrared light. This light is used to "pump" the Nd:YAG crystal, meaning it excites the neodymium ions embedded in the yttrium aluminum garnet crystal lattice. The laser diode is tuned to a wavelength that matches the absorption spectrum of the Nd ions, ensuring efficient energy transfer.

2. Nd:YAG Crystal:

The Nd:YAG crystal is the active gain medium. When the neodymium ions are excited by the pumping light, they absorb energy and move to a higher energy state. After a short period, these ions transition back to a lower energy state, releasing their stored energy in the form of photons. This process is called spontaneous emission.

For laser action to occur, a population inversion must be achieved, where more ions are in the excited state than in the lower energy state. As photons bounce back and forth between the mirrors of the laser cavity, they stimulate the excited Nd ions to release more photons of the same phase, direction, and wavelength. This process is known as stimulated emission, and it amplifies the light intensity within the crystal.

The laser cavity typically consists of two mirrors on either end of the Nd:YAG crystal. One mirror is highly reflective, and the other is partially reflective, allowing some light to escape as the laser output. The cavity resonates with the light, amplifying it through repeated rounds of stimulated emission.

To convert the fundamental frequency light (usually 1064 nm emitted by Nd:YAG) to green light (532 nm), a frequency-doubling crystal (such as KTP - Potassium Titanyl Phosphate) is placed in the laser's path. This crystal has a non-linear optical property that allows it to take two photons of the original infrared light and combine them into a single photon with twice the energy, and therefore, half the wavelength of the initial light. This process is known as second harmonic generation (SHG).

The result of this frequency doubling is the emission of bright green light at 532 nm. This green light can then be used for a variety of applications, including laser pointers, laser shows, fluorescence excitation in microscopy, and medical procedures.

This entire process is highly efficient and allows for the production of high-power, coherent green light in a compact and reliable format. The key to the DPSS laser's success is the combination of solid-state gain media (Nd:YAG crystal), efficient diode pumping, and effective frequency doubling to achieve the desired wavelength of light.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China