Semiconductor-pumped solid-state lasers are commonly used in Quasi-Continuous Wave (QCW) for high peak power output and in Continuous Wave (CW) for high average power output. In semiconductor-pumped solid-state lasers, the height of the heat sink and the spacing between chips (i.e., the combined thickness of the substrate and chip) significantly affect the product's cooling capacity. A larger spacing between chips results in better heat dissipation but increases the size of the product. Conversely, reducing the chip spacing decreases the product size but may compromise its cooling ability. Designing an optimally compact semiconductor-pumped solid-state laser that meets cooling requirements presents a significant challenge.

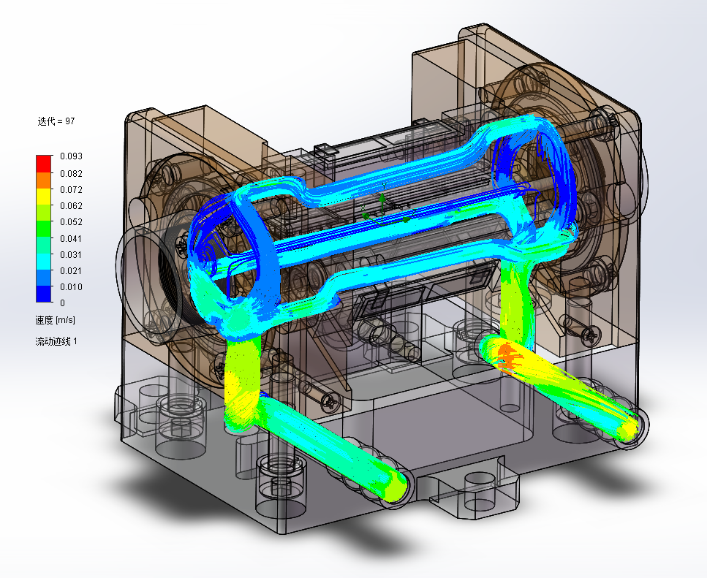

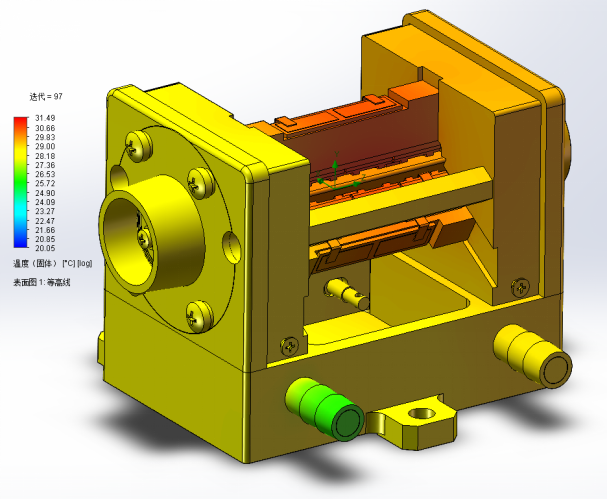

Lumispot Tech Group employs finite element methods to simulate and calculate the temperature field of devices. Thermal simulations are conducted by combining solid-state heat conduction steady-state thermal modeling with liquid temperature thermal modeling, targeting continuous operation conditions. As shown in the figure below, the optimal chip spacing and arrangement are proposed under solid-state heat conduction steady-state thermal modeling conditions. At this spacing and arrangement, the product not only exhibits excellent cooling capacity and lower peak temperatures but also maintains a compact structure.

In continuous or pulsed lasers, the heat generated in the laser medium from absorbing pump radiation and the external cooling of the medium cause uneven temperature distribution within the medium. This creates temperature gradients, altering the medium's refractive index and leading to various thermal effects. Internal heat deposition in the gain medium causes thermal lensing and thermally induced birefringence, resulting in certain losses in the laser system, affecting the stability of the laser in the cavity and the quality of the output beam. In continuously operating laser systems, as the pump power increases, the thermal stress within the gain medium also changes. These various thermal effects in the system significantly impede obtaining higher beam quality and output power in the entire laser system, which is one of the current challenges. Effectively suppressing and alleviating the thermal effects in crystals during operation has long puzzled scientists. In long-term research and experiments, the methods primarily employed to reduce the impact of thermal effects include optical compensation, effective heat dissipation, optimizing cavity parameters, and selecting superior performance media. Recent studies show that bonded crystals formed through thermal bonding technology are considered effective in solving thermal effect issues in laser gain media, thus becoming a current research focus.

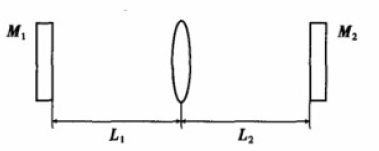

In high-power solid-state lasers, which have a high electro-optic conversion efficiency, the large pump power causes the laser medium to absorb a lot of heat, leading to a thermal lensing effect that severely affects the laser's output performance. In such cases, the laser can be approximated as a lens with a wide focal length, as illustrated below.

In the development project of high-power LD-pumped Nd:YAG lasers, the issue of thermal lensing in Nd:YAG laser cavities has been addressed, enabling the module to achieve high beam quality while obtaining higher power.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China