Is a Laser Diode a semiconductor laser?

Yes. A laser diode is a special kind of semiconductor laser. It works by using the science of semiconductors and a special semiconductor material to make laser light. Inside a laser diode, this material is made in a way that gets more excited electrons than relaxed ones, causing the excited ones to give out laser light when they calm down. This creates a focused and single-color light called a laser. The word "diode" in "laser diode" means it's made like a certain type of basic semiconductor device, called a p-n junction diode, which helps create the right conditions for making the laser light by arranging two types of semiconductor materials. (Botez & Avram, 2014).

Botez, D., & Avram, R. (2014). Fundamentals of Semiconductor Lasers. In Introduction to Solid-State Lighting (pp. 101-152).

Springer, Cham. [DOI: 10.1007/978-3-319-03229-4_4]

A Laser Diode (LD, injection laser diode, ILD, or Diode Laser), is a semiconductor device that produces focused and single-color light using stimulated emission. It works on the principle of amplifying light through stimulated emission of radiation (abbreviated as LASER), achieved by creating a specific arrangement within a semiconductor material. This arrangement allows photons to be emitted in an organized way, resulting in a concentrated and intense beam of light with a distinct wavelength. laser diode stacks are like a team of laser diodes working together in one package or array. This setup makes the combined laser light more robust and more powerful.

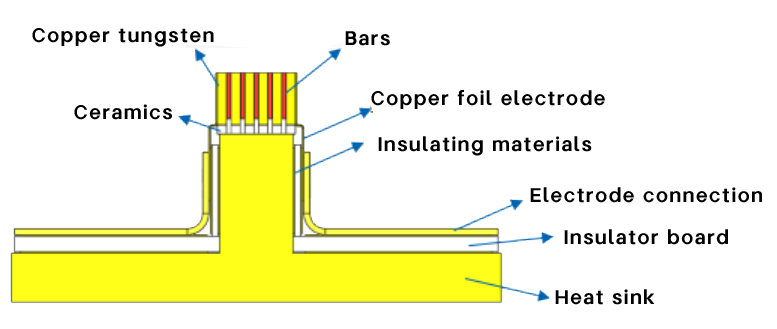

The structure of Laser Diode Horizontal Stacks from Lumimetric:

Diode lasers are important devices that generate light using an optical gain medium and a resonant optical cavity. These components' design is crucial for modern lasers. A diagram of a laser cavity is shown, including an optional mode selection filter for one cavity mode. The gain medium absorbs radiation but can amplify it with input energy, creating light. The resonant optical cavity supports multiple modes, and if the gain overcomes losses, a mode reaches the threshold, emitting coherent light. Different methods are used for single-mode preference. Diode lasers have broad applications, like in CD/DVD players, fiber-optic communication, laser printers, and more (Coldren, Corzine, & Mašanović, 2012).

Coldren, L. A., Corzine, S. W., & Mašanović, M. L. (2012). Diode lasers and photonic integrated circuits.John Wiley & Sons, Inc.

https://doi.org/10.1002/9781118148167

In-plane lasers, also known as edge-emitting lasers, have been around since the late 1960s. Feedback for Edge-Emitting Lasers is often achieved using a simple cleaved-facet mirror, which reflects the light back into the laser cavity for amplification.

Horizontal Linear Laser Diode

Horizontal Laser Diode Stacks From Lumispot Tech Group(Lumimetric is one of the wholly-owned subsidiaries)

DPSS laser (Diode Pumped Solid State Laser) devices are all horizontally stacked arrays and are generally provided with side pumping in the DPL.

(2023 Latest Diode Pump Solid State Laser)G2-A DPSS

are a type of semiconductor laser that emits light in a direction perpendicular to the surface of the semiconductor wafer. Unlike traditional edge-emitting lasers where light travels along the wafer surface, VCLs emit light upwards or downwards through a vertical cavity structure. This design enables efficient light emission and provides advantages such as low threshold currents, circular beam profiles, and ease of integration into optical systems.

The majority of hair removal devices are mounted by vertical stacked arrays (808nm wavelength), which include flat vertical stacks and curved vertical stacks

Surface-emitting lasers, primarily known as Vertical-Cavity Surface-Emitting Lasers (VCSELs), are a specialized form of laser diodes that differ notably from traditional edge-emitting lasers. These semiconductor lasers emit light perpendicular to the wafer's surface, in contrast to edge-emitting lasers that release light along the surface. This unique emission method allows for the light to be emitted directly from the top surface of the chip. VCSELs are renowned for their low threshold currents, high efficiency, and the ability to form two-dimensional arrays, alongside their excellent beam quality. These advantages facilitate seamless integration with other components, efficient coupling to optical fibers, and the creation of laser arrays. Owing to these features, VCSELs find extensive applications in various domains, including data communication, sensing, medical applications, and consumer electronics, leveraging their distinct design for enhanced performance and versatility.

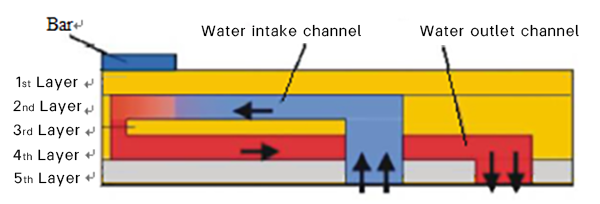

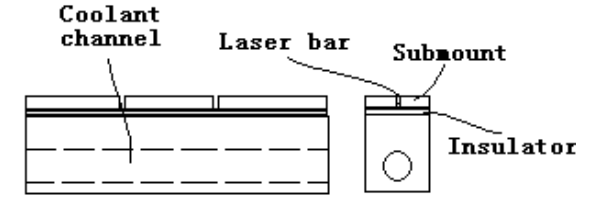

The heat sink is prepared with closely spaced waterways and bars, typically around 0.15-0.2mm apart, resulting in a small thermal resistance and efficient heat dissipation. The monolithic device boasts high power capabilities (continuous wave operation up to 100W or more, and quasi-continuous wave operation up to 700W). Additionally, the heat sink serves as a positive electrode, necessitating high-quality cooling water such as deionized water.

Heat sink preparation is simplified with slightly wider spacing between water channels and bars, typically exceeding 0.2mm. Water channels often incorporate through-holes or specialized tooth structures designed to enhance exchange surface area. Macro channel structures like hair removal modules, DPL modules, and 10,000-watt ring bars fall within this category. Heat sinks featuring waterways typically don't function as conductive mediums and don't necessitate high water quality. (Chen,Liu&Duan, 2021)

Chen, K., Chen, L., Liu, Q., & Duan, Y. (2021). Design and Experiment of High Power Diode Laser Array Heat Sink Based on Heat Transfer and Fluid Flow Analysis.

Journal of Applied Thermal Engineering, 192, 116935. https://doi.org/10.1016/j.applthermaleng.2021.116935

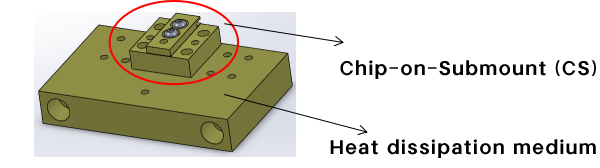

Chip-on-Submount (CS) is the prevalent cooling method, widely adopted by laser diode stacks for effective heat dissipation. This approach is suitable for devices with relatively low average power: single bar power below 60W for Chip-on-Submount, and below 3W for Laser Diode stacks. Heat dissipation relies on close-contact conduction with assistance from other heat carriers. Indium foil or thermal conductive silicone grease is often utilized for this purpose. The carrier may integrate a waterway or a semiconductor chiller (TEC) along with a fan to efficiently dissipate heat (Li, Yan&Zhou, 2019).

Li, B., Yan, L., Zhu, J., Xie, J., Zhou, C., Liu, J., ... & Wang, Y. (2019). High-power diode laser stacks for Fiber Laser pumping.

Proceedings of SPIE, 10899, 108990A. https://doi.org/10.1117/12.2508641

The typical wavelength range of a laser diode falls within the near-infrared to the visible spectrum, covering approximately 400 to 2000 nanometers (nm) of wavelengths. This range accommodates various applications requiring specific colors of light emission. For instance, red laser pointers often operate around 650 nm, while infrared laser diodes, employed in communication systems and remote controls, generally fall within the range of 850 nm or higher. It's important to note that specialized laser diodes can also exist outside this range for specific industrial, scientific, and medical purposes (Hecht, J. 2002).

Hecht, J. (2002). The LASER Guidebook (2nd ed.). McGraw-Hill Education.

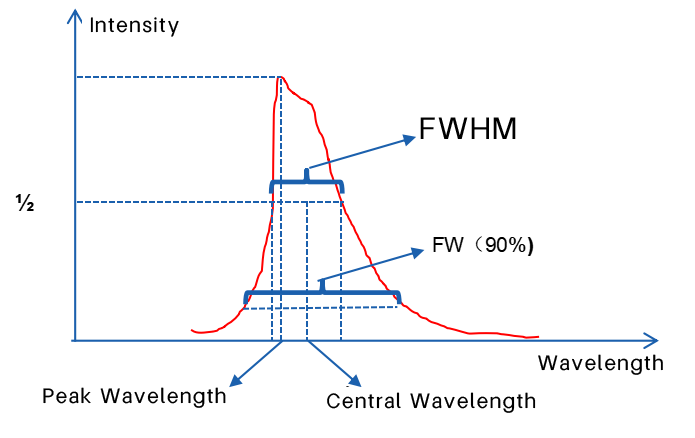

→ The wavelength parameters include the center wavelength, peak wavelength, FWHM (full-width half maximum), and FW (90%);

→ Wavelengths undergo a redshift as the junction temperature increases, generally around 0.26-0.28 nm/°C. Higher current/larger duty cycle/weaker heat dissipation will all lead to higher junction temperatures;

→ The spectral width of an array is wider compared to that of a single bar.

1. Visible Spectrum (400-700 nm): Used in laser pointers, barcode scanners, and laser printers due to compact size and low power requirements.

2. Near-Infrared (700-1500 nm): Applied in fiber-optic communication, medical skin treatments, and solid-state laser pumping.

Read the full article about the Near-infrared laser here.

3. Short-wavelength infrared (1500-3000 nm): Utilized in spectroscopy, gas sensing, and material processing applications.

4. Mid-wavelength infrared (3000-8000 nm): Found in remote sensing, targeting, and environmental monitoring.

5. Far-Infrared (Above 8000 nm): Employed in medical diagnostics, gas analysis, and industrial heat treatment.

Versatility: Laser diodes' adaptability across these wavelengths underscores their importance in various industries and technologies.

Laser diodes and light-emitting diodes (LEDs) are both semiconductor devices that emit light, but they differ in their fundamental operating principles, characteristics, and applications:

| Laser Diode (LD) | Light Emitter Diode (LED) |

Coherence and Monochromaticity:Laser diodes emit coherent and monochromatic light, meaning the emitted light waves are in phase and have a single wavelength. | Incoherent and Broad Spectrum:LEDs emit incoherent light with a broader spectrum, producing light with varying wavelengths. |

Stimulated Emission:Laser diodes operate based on the principle of stimulated emission, where excited electrons release photons that trigger the emission of additional photons in a cascade effect. | Spontaneous Emission:LEDs operate based on spontaneous emission, where excited electrons release photons without triggering additional photon emissions. |

Directionality:Laser diodes emit highly directional light in a narrow beam, making them suitable for applications requiring precise focusing and long-range projection | Omni-Directional:LEDs emit light in a wider angle, making them suitable for illuminating larger areas or displays. |

High Intensity:Laser diodes produce intense and focused light, making them ideal for applications like laser cutting, engraving, and medical procedures. | Lower Intensity:LEDs produce lower-intensity light compared to laser diodes, making them commonly used for indicator lights, displays, and general lighting. |

Laser Diode Applications:Laser diodes are used in telecommunications, medical treatments, optical storage, precision measurement, and scientific research. | Light Emitter Diode Applications:LEDs are used in indicator lights, displays, lighting fixtures, automotive lighting, traffic signals, and backlighting for screens. |

Saleh, B. E. A., & Teich, M. C. (2007). Fundamentals of photonics (2nd ed.). Wiley.

Coldren, L. A., Corzine, S. W., & Mašanović, M. L. (2012). Diode lasers and photonic integrated circuits. John Wiley & Sons, Inc.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China