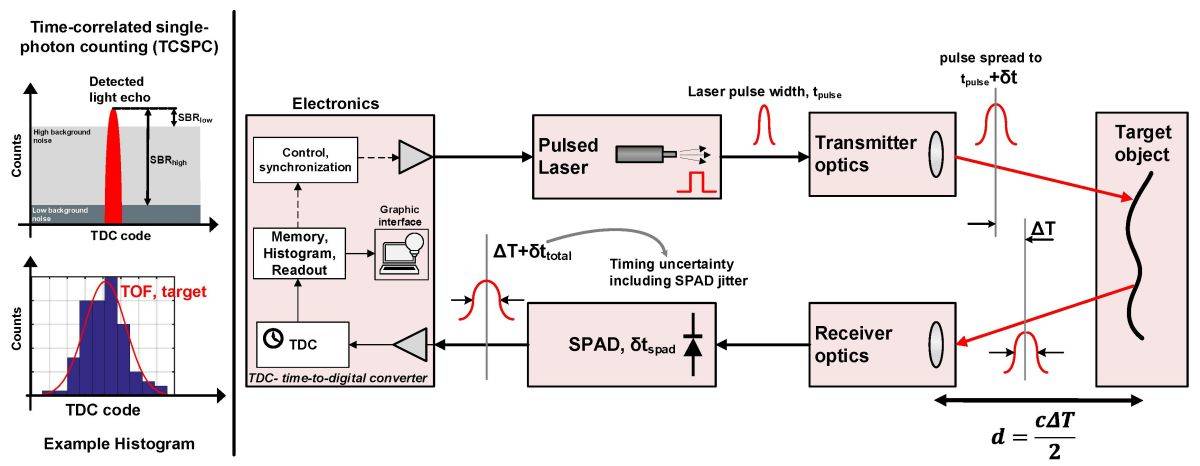

In the realm of distance measurement and object detection, direct Time-of-Flight (dTOF) technology stands out for its precision and efficiency. The principle behind dTOF, as introduced in the first chapter, is straightforward: it employs Time-Correlated Single Photon Counting (TCSPC) to directly measure the flight time of light. A specific dTOF system, illustrated below (referenced), alongside AMS's TOF Proximity Sensor Module, reveals the intricacies of its emitter, receiver, and module pins. By analyzing both the system's schematic and the actual module, we can delve into the fundamental principles, core components, and system parameters of dTOF.

Click here for Understanding Time of Flight Systems: TOF,iTOF,and dTOF

At the heart of the emitter circuit lies the Laser Driver, a pivotal component tasked with driving the laser. It controls the emission of digital pulse signals, typically modulating MOSFETs for laser emission.

The laser, a critical component in dTOF, is chosen for its narrow spectrum, high energy intensity, fast modulation, and ease of integration. Consumer electronics predominantly utilize Vertical Cavity Surface Emitting Lasers (VCSELs) for their dTOF applications due to these benefits. However, applications in other platforms, especially in automotive LiDAR, might opt for higher power Edge Emitting Lasers (EEL) or Fiber Lasers. Typically, dTOF systems in electronics choose lasers with wavelengths of 850 nm or 940 nm, with the selection heavily influenced by their absorption peaks and noise considerations under sunlight.

TOF Ranging pulsed fiber laser

The emitter side employs a simple optical lens to direct the laser energy within the desired field of view. Some applications might use collimators plus Diffractive Optical Elements (DOEs) to divide the VCSEL's beam into multiple angles.

On the receiver side, optics are crucial for collecting light within the target field of view. A lens with a smaller F-number and higher relative illumination is preferred, often treated with coatings to enhance transmissivity while using narrowband filters to eliminate out-of-band light interference.

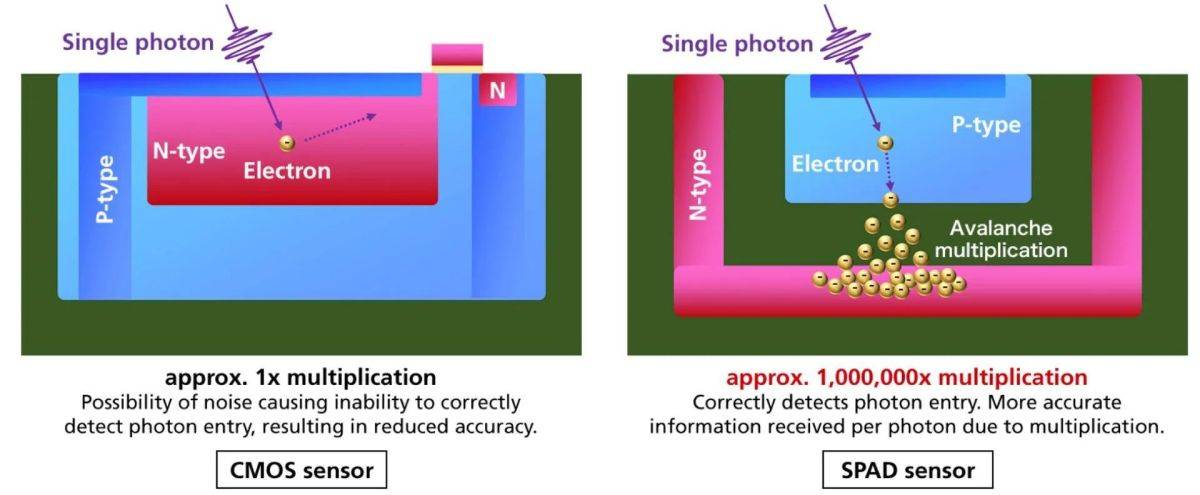

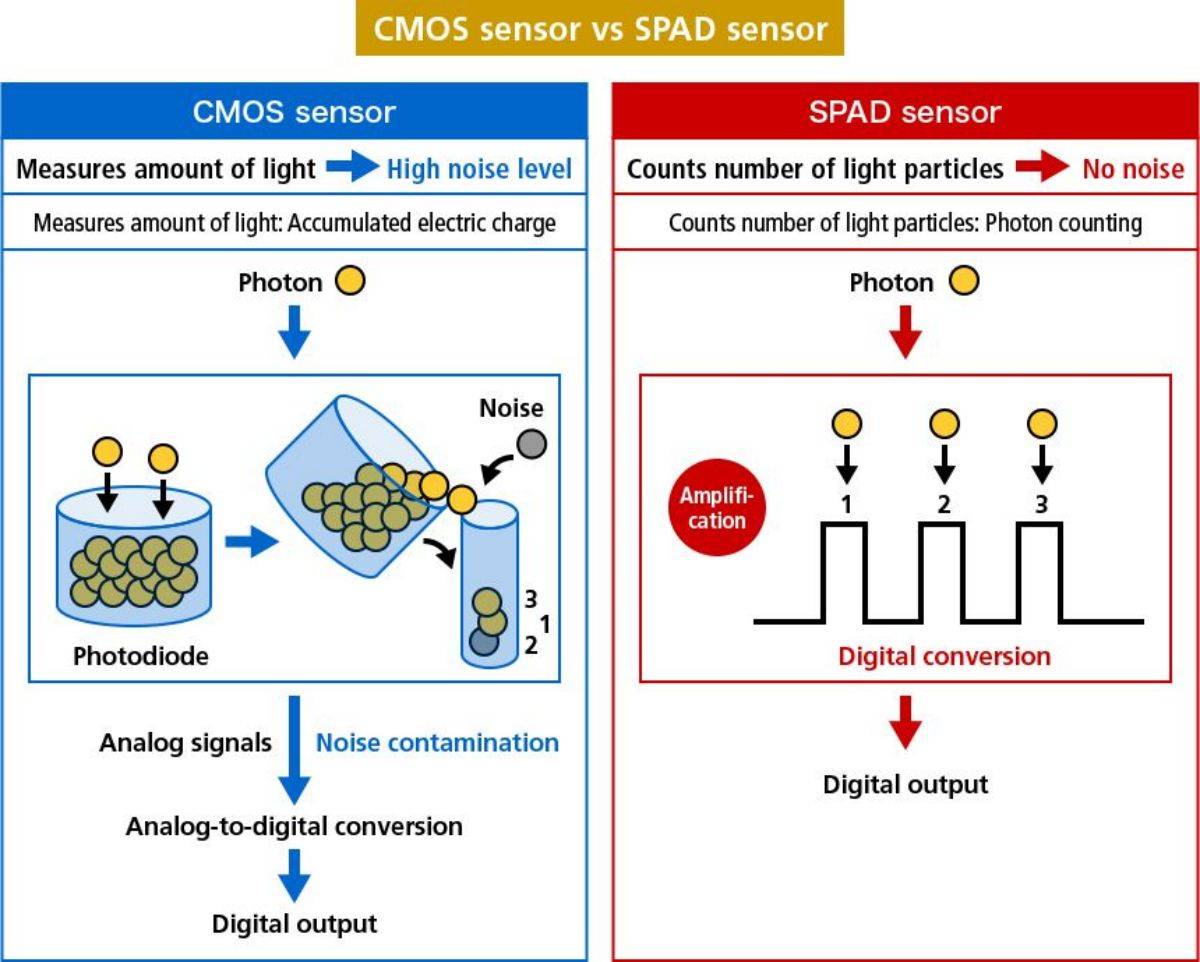

For detection, dTOF systems predominantly utilize Single-Photon Avalanche Diodes (SPADs) or Silicon Photomultipliers (SiPMs), with the key difference being that each SiPM pixel contains multiple SPAD elements. Unlike traditional CMOS sensors, SPADs can respond to single photons, triggering a significant avalanche current with each detection, effectively offering a binary output of light presence.

The Time-to-Digital Converter (TDC) translates analog signals into time-represented digital signals, marking the pulse times relative to a start point. This data, processed into histograms, helps determine the position of objects by comparing peak histogram counts.

The theoretical detection range of dTOF is limited only by the system's ability to discern reflected photons from noise, influenced by the emitted wavelength's signal-to-noise ratio on the target surface. Factors like the laser modulation frequency impact the maximum unambiguous detection range, introducing considerations for pulse separation to avoid signal overlap and ambiguity.

dTOF's distance measurement precision inherently depends on the pulse width of the emitted laser, while its accuracy is affected by various uncertainties introduced throughout the signal's journey from emission to detection. These include the timing precision of the laser driver, SPAD's response time, and TDC's accuracy.

Addressing background noise and crosstalk is crucial for dTOF systems. Strategies include utilizing SPADs with varied attenuation levels to handle diverse lighting conditions and employing algorithms to mitigate reflection-induced crosstalk.

Despite the larger pixel size of SPADs compared to traditional CMOS sensors, advancements in back-illuminated SPAD technology by manufacturers like Sony are increasing photon absorption rates and filling factors, promising higher spatial resolutions for dTOF systems. Additionally, the pulsed nature of dTOF transmission ensures lower power consumption relative to continuous-wave systems.

The design and manufacture of dTOF systems encompass high-speed electronic circuits, laser emission control, and SPAD-related electronics, presenting significant challenges. The availability of SPAD providers is limited, and the high voltage requirements for SPAD operation add complexity to circuit design.

In summary, dTOF technology exemplifies a sophisticated blend of optical and electronic engineering, offering high precision and efficiency in distance measurement and object detection. However, the technological complexity and associated costs underscore the need for continued innovation and optimization in the field.

From the web page 02.02 TOF系统 第二章 dTOF系统 - 超光 Faster than light (faster-than-light.net)

by the author: Faster than light

Disclaimer:

We hereby declare that some of the images displayed on our website are collected from the Internet and Wikipedia, with the aim of promoting education and information sharing. We respect the intellectual property rights of all creators. The use of these images is not intended for commercial gain.

If you believe that any of the content used violates your copyright, please contact us. We are more than willing to take appropriate measures, including removing images or providing proper attribution, to ensure compliance with intellectual property laws and regulations. Our goal is to maintain a platform that is rich in content, fair, and respects the intellectual property rights of others.

Please contact us at the following email address: sales@lumispot.cn. We commit to taking immediate action upon receiving any notification and guarantee 100% cooperation in resolving any such issues.

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China