Lumispot Technology Co., Ltd. (hereinafter referred to as Lumispot Tech) has developed a new generation of high uniformity, high brightness fiber-coupled semiconductor lasers based on its proprietary technology. Along with a precision optical scheme designed in-house, it has achieved a square light spot laser system capable of wide viewing, high uniformity, high brightness, and continuous operation.

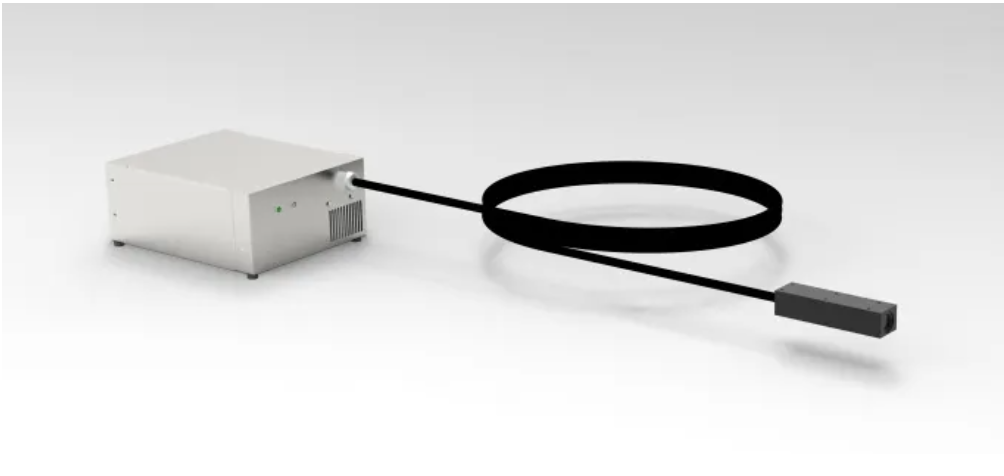

This series of products, independently developed by Lumispot Tech, uses fiber-coupled semiconductor lasers as the light source. It incorporates high-precision control circuits and introduces the laser into an optical lens via fiber transmission, ultimately achieving a square light spot laser output at a fixed divergence angle.

The main application of this series is the detection of light and dark areas on photovoltaic cell panels. Final inspection of the cell panel assembly includes EL electrical measurement and PL optical measurement to classify the assembly based on its luminous efficiency. In this process, traditional line PL cannot distinguish between light and dark products. After the finished cell assemblies are series and parallel connected, the presence of dark cells can lead to product downgrading. Using the square light spot system allows for non-contact, efficient, and synchronous surface PL inspection of different areas of the cell assembly. By analyzing the imaging of the assembly board, light and dark cells can be identified, preventing component failure due to low luminous efficiency of individual silicon cells.

Selectable performance and high reliability: The system's output power is selectable, ranging from 25W to 100W, catering to different inspection schemes for photovoltaic cells, and is highly reliable based on single-tube fiber coupling technology.

Multiple control modes available: The laser system has three control modes, allowing customers to independently control it based on on-site conditions.

High uniformity of the light spot: The system, known for its stable brightness and high uniformity, helps in distinguishing between light and dark cells and selecting out abnormal cells.

| Parameter | Unit | Value |

| Max. Output Power | W | 25/50/100 |

| Central Wavelength | nm | 808±10 |

| Fiber Length | m | 5 |

| Working Distance | mm | 400 |

| Spot Size | mm | 280*280 |

| Uniformity | % | ≥80% |

| Rated Working Voltage | V | AC220 |

| Power Adjustment Method | - | RS232 Serial Port Adjustment Modes |

| Operating Temp. | °C | 25-35 |

| Cooling Method | Air Cooled | |

| Dimensions | mm | 250*250*108.5(Without lens) |

| Warranty Life | h | 8000 |

* Control Mode:

Mode 1: External Continuous Mode

Mode 2: External Pulse Mode

Mode 3: Serial Port Pulse Mode

※ Lumispot Tech can develop custom products based on customer needs. If you are interested in our products, please contact us in a timely manner!

Compared to line array detection schemes, area array cameras can complete the imaging and detection of silicon wafers in the entire effective area at once. A uniformly illuminated area light spot ensures uniform illumination and synchronous excitation across the silicon wafer. If there are anomalies in the cell, they can be clearly imaged.

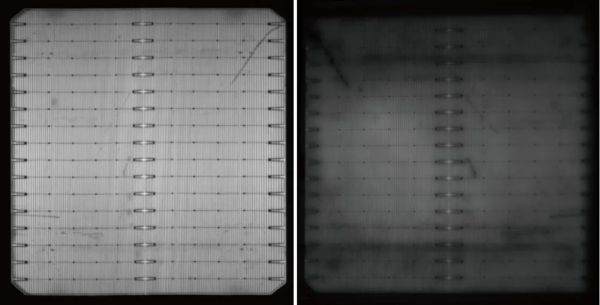

The figure below shows the detection of the same cell using both Line PL and Area PL solutions, with Area PL clearly identifying dark cells.

Figure 2: Comparison of Line PL and Area PL Detection Patterns

(Left: Line PL Solution, Right: Area PL Solution Using Square Spot Light Source System)

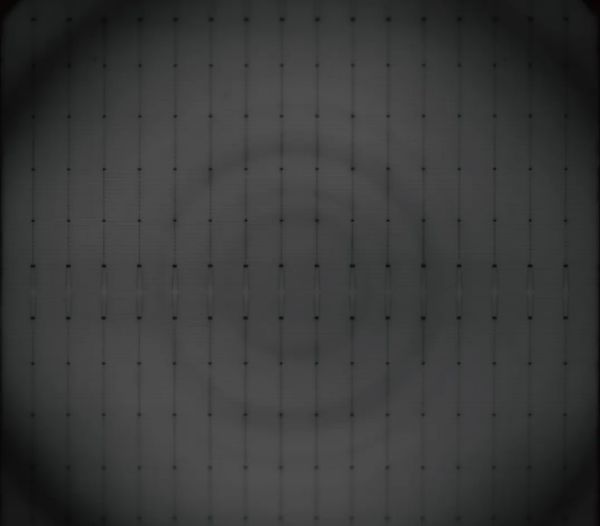

Additionally, Area PL can also identify concentric circle cells that move to the finished product stage, as shown in the following figure:

Figure 3: Concentric Circle Cell Patterns Detected by Area PL

The Area PL solution is more flexible in its application scenarios. It does not require moving the component during photography, making it more tolerant of equipment mechanics.

It can distinguish between light and dark cells, avoiding product degradation due to individual cell defects.

The light spot has an area distribution, resulting in a lower energy density per unit area and higher safety.

Lumispot Tech, as a national specialized and new "Little Giant" enterprise, has always been dedicated to providing product solutions for various laser pumping sources, light sources, and related application systems in specialized fields. The company is among the first batch of enterprises in China to master the core technology of high-power semiconductor lasers, involving multiple professional fields such as materials, thermal science, mechanics, electronics, optics, software, algorithms, etc. It encompasses dozens of internationally leading core technologies and key processes, including high-power semiconductor laser packaging, thermal management of high-power semiconductor laser arrays, laser fiber coupling, laser optical shaping, laser power supply control, precision mechanical sealing, high-power laser module packaging, and precision electronic control. It has obtained over a hundred intellectual property rights, including authorized national defense patents, invention patents, and software copyrights. Lumispot Tech values research and development, focuses on product quality, and adheres to the corporate principles of prioritizing customer benefits, continuous innovation, and employee growth, striving to become "a global leader in the field of laser specialty information."

Contact: Lumispot

Phone: +86-15072320922

Tel: +86-510-87381808

Email: sales@lumispot.cn

Add: Bldg 4 No.99 Fu Rong 3rd Road, Wuxi, China